Introduction:

The advent of 3d druck material technology has transformed the landscape of manufacturing, heralding a new era of innovation and customization. From intricate prototypes to functional end-use products, 3D printing has revolutionized various industries, offering unprecedented flexibility, efficiency, and cost-effectiveness. This article explores the evolution, applications, challenges, and future prospects of 3D printing technology, shedding light on its transformative potential.

Evolution of 3D Printing:

3D printing, also known as additive manufacturing, traces its roots back to the 1980s when the first rudimentary techniques were developed. Over the decades, advancements in materials science, software development, and printing technology have propelled 3D printing into the mainstream. What once started as a niche technology primarily used for rapid prototyping has now evolved into a versatile manufacturing tool capable of producing complex geometries with precision and speed.

Applications Across Industries:

The versatility of 3D printing technology transcends industry boundaries, finding applications in aerospace, automotive, healthcare, consumer goods, and beyond. In aerospace, 3D printing enables the production of lightweight, high-performance components, leading to fuel efficiency and cost savings. In healthcare, it facilitates the customization of medical implants and prosthetics, enhancing patient care and comfort. Additionally, the automotive industry utilizes 3D printing for rapid prototyping, custom tooling, and even production of limited-edition parts, streamlining the manufacturing process and reducing lead times.

Challenges and Limitations:

Despite its myriad benefits, 3D printing faces several challenges and limitations that impede its widespread adoption. One of the primary challenges is the limited range of materials suitable for 3D printing, constraining its application in certain industries. Moreover, scalability and production speed remain significant hurdles, especially for mass production scenarios where traditional manufacturing methods may still hold an advantage. Quality control and post-processing requirements also pose challenges, as ensuring the structural integrity and surface finish of printed parts often requires additional steps and expertise.

Future Prospects and Emerging Trends:

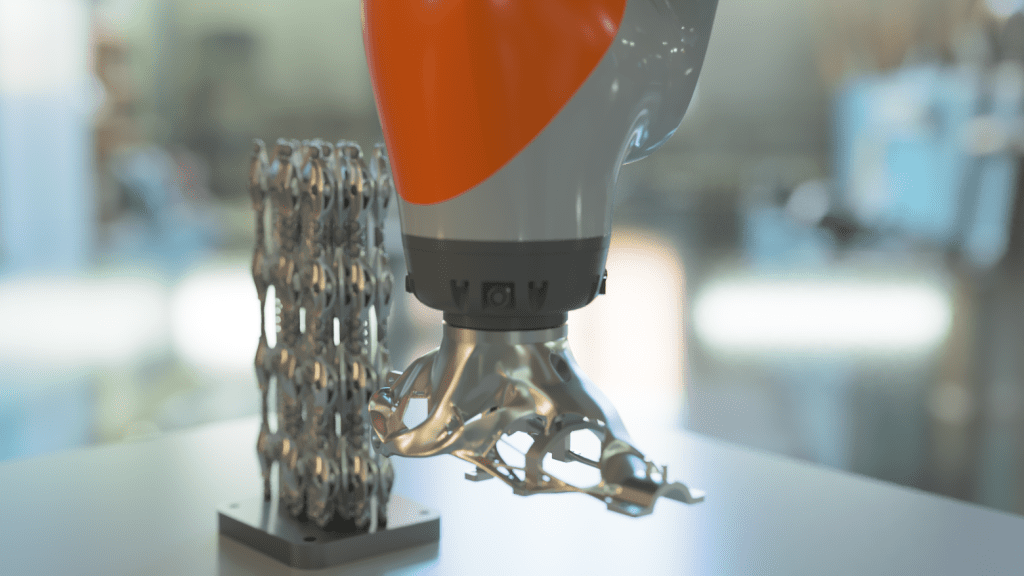

As research and development in 3D printing continue to progress, the technology holds immense potential for further innovation and disruption. Emerging trends such as multi-material printing, continuous 3D printing, and bioprinting are expanding the scope of applications across various sectors. Multi-material printing enables the fabrication of hybrid structures with diverse properties, opening new possibilities in fields like electronics and consumer goods. Continuous 3D printing, utilizing robotic arms and conveyor systems, promises to revolutionize large-scale manufacturing by significantly reducing production time and costs. Furthermore, bioprinting holds promise for tissue engineering and regenerative medicine, with the potential to revolutionize healthcare by enabling the fabrication of patient-specific organs and tissues.

Conclusion:

In conclusion, 3D printing technology represents a paradigm shift in manufacturing, offering unparalleled flexibility, customization, and efficiency. While challenges and limitations persist, ongoing research and technological advancements continue to expand the capabilities and applications of 3D printing. As the technology matures and becomes more accessible, its transformative impact will likely reshape industries and redefine the way we design, produce, and consume goods. With innovation driving progress, the future of 3D printing holds boundless potential, poised to revolutionize manufacturing on a global scale.